Dried Filament But Still Clogged? 5 Things To Check

Sometimes, even when your filament is dry, clogging can still happen and might ruin your prints. 3D printing is a delicate process, and a lot can go wrong due to factors such as moisture. Moisture is usually the biggest culprit when it comes to clogging. This is because hygroscopic filaments, such as Nylon, PETG, and TPU, can easily absorb moisture from the air.

However, even after you have dried your filament using a filament dryer, it does not guarantee 100% clog-free 3D printing. Here are the five things to check when you are still getting a clogged print even though you have thoroughly dried it using a filament dryer.

The Issue of Heat Creep

You might not be familiar with the term “heat creep.” It occurs when heat from the hotel rises too high, reaching the point where it breaks into the cold zone. This warms the filament even before it reaches its boiling or melting points.

Hence, when the filament is softened prematurely, it swells and jams the path. PLA is known to have this issue due to its low softening temperature. Moreover, the print will work fine for the first hour, and after that, it suddenly clogs or underextrudes.

So, how do we fix this issue? Here are some of the things you can try:

- Ensure that your cooling fan for the heat break is running perfectly.

- Consider purchasing an all-metal hotend with a high-quality heat break.

- Try reducing the hotel temperature slightly or improving the airflow.

Once you incorporate some of these fixes, you will notice that the issue of heat creep will stop.

Carbonized Residue in the Nozzle

Over time, even the highest-quality filaments can leave tiny residue in the printer’s hot end. At higher temperatures during the slow printing process, numerous temperature changes occur.

This leaves a carbon residue in the nozzle, which will ultimately act as a blockage. Once the blockage occurs, the extrusion path will start to narrow, resulting in issues such as under-extrusion, poor flow, and even full or partial clogging.

Here are some things you could do to fix the carbonized residue issue in the nozzle:

- Use a cold pull by using a cleaning filament to reduce any buildup of carbon.

- You can even use a brass brush and blowtorch combination after removing the nozzle to clean it.

- Brass nozzles degrade over time, especially with abrasive filaments, so be sure to replace them periodically.

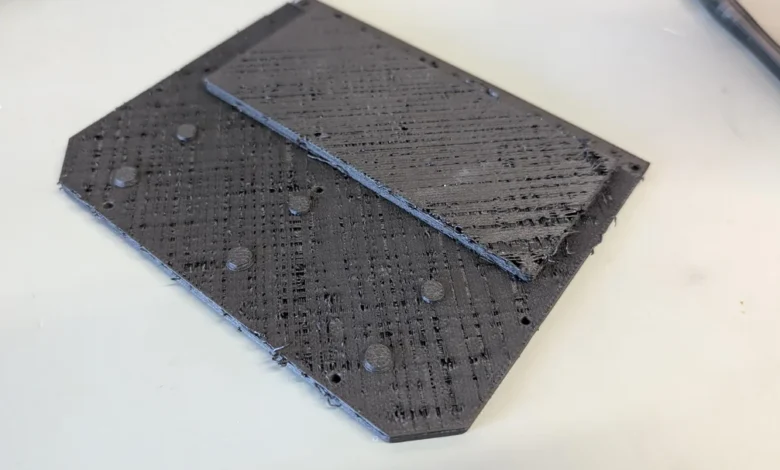

Nozzle Wear or Internal Damage

Even if your filament is dry, it can cause a problem when pushed through an old, damaged, or worn-out nozzle. This is especially true with abrasive materials like carbon fiber, glow-in-the-dark, or other filaments. If you don’t have a hardened steel nozzle or something that isn’t affected by abrasive materials, then you can have a rough interior.

Once the filament goes through that rough interior, it can cause inconsistent flow, ultimately leading to blockages. Here’s how you can fix it:

- Inspect your nozzle regularly, and if you notice any inconsistent results or print lines on the 3D printer object, you will need to change the nozzle.

- Use brass nozzles for PLA or PETG. For other materials, a hardened steel or ruby nozzle is just better.

By following these two tips, you can easily prevent nozzle wear and damage, ultimately avoiding clogging.

Dust Particles in Filament’s Way

Dry filaments are beneficial, but when dust, dirt, or other particles accumulate on the spool, it can ultimately lead to nozzle blockages. Therefore, when these particles melt unevenly, they tend to accumulate within the nozzle. Of course, this is quite an extreme example of it happening.

However, it is essential to ensure that your filaments are stored in a suitable environment. If it does, then the outer surface may become damaged or oxidized, potentially causing nozzle blockages.

Also, try wiping the filament before starting the extruding process. Moreover, before every print, you should also see if the extruder gears are precise. Once you incorporate these fixes, your filaments will start to print more reliably, ultimately yielding the best 3D printing results.

Bad Retraction Settings

Retraction settings mean how far and how quickly the filament is pulled back from the hotend during travel moves. Generally, this prevents oozing and stringing, resulting in clean, accurate, and better outcomes.

However, over-retraction speed can pull the softened filaments into the cooler zones, where they will harden and become sticky. The results? Well, it can lead to both partial and complete clogs, especially in specific setups.

Retraction can also increase wear and tear on your nozzle, potentially leading to clogging issues. Firstly, you need to carefully tune your retraction settings. Moreover, you can even use a temperature tower to find the lowest extrusion temperature. This will give you better print flow.

You should also avoid printing a stringy model that+98 requires excessive retraction.

Bonus: Buying a Top Quality Filament & Dryer

Counterfeit filaments can have their issues. Some of them can contain impurities, inconsistent diameters, and even poor additives that can clog your nozzle. Moreover, a faulty filament dryer is also a culprit if it fails to dry your filaments properly.

A filament like Chitu E1 is the perfect example of what a great dryer should be. It features a temperature monitor and a dedicated humidity monitor as well. Therefore, choosing the right filament is essential to avoid clogging.

Final Verdict

Clogged filaments can be a significant issue, especially if the problem persists after you dry them. With our five fixes, you can have the best possible results while eliminating nozzle clogging. Lastly, if you want to get the best 3D printing accessories, then visit Chitu Systems.