How Waterproof Labels Reduce Customer Complaints About “Unreadable” Sticker

In almost every product category—whether it’s skincare, candles, frozen food, supplements, electronics, handmade items, or shipping packages—labels play a crucial role in informing, guiding, and reassuring customers. But there’s one recurring customer complaint found across online marketplaces, retail stores, and social media reviews:

“The label became unreadable.”

This includes issues like:

Smudged text

Peeling labels

Faded barcodes

Oil-soaked stickers

Water-damaged print

Worn-off safety warnings

Wrinkled ingredient lists

When customers cannot read important information, their perception of the brand declines sharply. Unreadable labels are not just a cosmetic failure—they impact compliance, safety, usability, and trust.

The good news? Waterproof labels directly eliminate the root causes of these complaints.

This article explains exactly why unreadable labels happen, how waterproof labels prevent these issues, which industries benefit the most, and how switching to waterproof materials can significantly increase customer satisfaction—and reduce returns, complaints, and bad reviews.

Why Customers Complain About “Unreadable” Stickers

Before exploring waterproof label solutions, we must understand why labels become unreadable in the first place. Most complaints arise from environmental exposure or handling conditions that paper-based labels simply cannot survive.

Common causes include:

1. Water exposure

Rain, splashes, humidity, and condensation can instantly cause paper labels to wrinkle or bleed.

2. Oils and lotions

Skincare, candles, food packaging, and chemical products often come into contact with oil, which destroys standard paper labels.

3. Heat

Candle jars, cosmetics, and shipping environments often create enough warmth to weaken adhesive or warp labels.

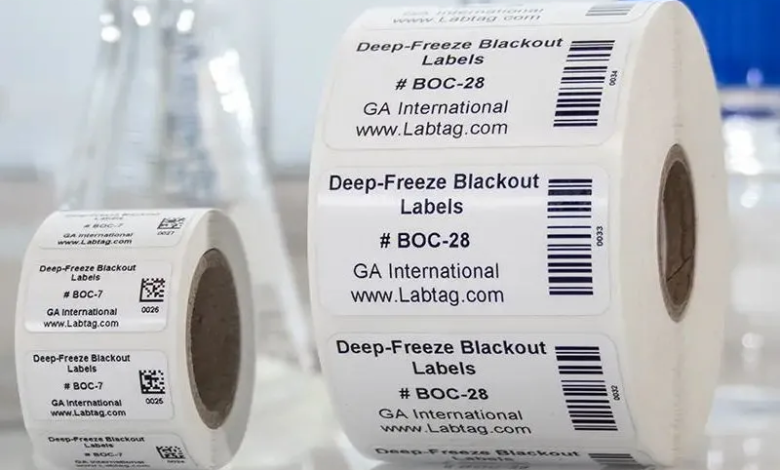

4. Refrigeration and freezing

Condensation forms on containers, ruining paper labels or causing bubbling and peeling.

5. Frequent handling

Products touched daily—like skincare tubes or drink bottles—cause labels to smudge or fade.

6. Friction during shipping

Packages rub against conveyor belts, poly mailers, and other cartons, wearing down fragile labels.

7. Poor adhesive performance

Paper labels often lift at the edges, peel off, or slip out of alignment over time.

8. Printed text fading

Inkjet and low-quality direct thermal prints can fade quickly under harsh conditions.

When labels fail, customers feel frustrated, confused, or misled—especially when they lose access to important information.

How Waterproof Labels Reduce Customer Complaints About Unreadable Stickers

Waterproof labels solve these problems at the root by using durable, moisture-resistant, oil-resistant, and smudge-proof materials that protect both the printed text and the adhesive bond. Here’s how they drastically reduce complaints.

Waterproof Labels Reduce Customer Complaints by Preventing Water Damage

Why water exposure ruins normal labels

Paper labels absorb water instantly. They wrinkle, dissolve, smear, and discolor. Humidity can also cause the print to fade or bubble.

How waterproof labels eliminate water complaints

Waterproof labels:

Repel water

Do not absorb moisture

Maintain shape and clarity even when fully submerged

Provide crisp readability after rain, washing, or shower storage

Remain intact during condensation cycles

Ideal for:

Soap and bath products

Beverage bottles

Outdoor equipment

Food containers

Refrigerated products

Waterproof Labels Reduce Customer Complaints by Resisting Oils & Grease

Why oils destroy standard labels

Oils and lotions dissolve the ink on paper labels, weaken adhesive, and cause the entire label to smear or peel away.

How waterproof labels solve the oil problem

Waterproof labels:

Resist oils, lotion residue, wax, plant oils, and fragrance oils

Prevent smudging when customers touch products with oily hands

Keep ingredient lists and branding fully visible

Maintain adhesion on slippery surfaces

Especially important for:

Skincare bottles

Aromatherapy products

Candle jars

Hand creams and salves

Haircare items

Cooking oils

Waterproof Labels Reduce Customer Complaints by Withstanding Heat & Temperature Changes

Why temperature affects label readability

Heat can:

Loosen adhesive

Cause paper to yellow or curl

Cause text to fade

Warp labels on curved containers

How waterproof materials improve heat resistance

Waterproof labels maintain:

Adhesive grip

Print clarity

Shape and structure

Durability

Even when exposed to:

Candle heat

Warm car interiors

Body heat

Hot shipping environments

Bathroom temperature changes

Waterproof Labels Reduce Customer Complaints by Preventing Smudging & Fading

Why smudging happens

Paper labels printed with inkjet or uncoated thermal technology smear easily when touched or rubbed.

How waterproof labels prevent smudges

Waterproof labels offer:

Smudge-proof printing

Scratch resistance

Long-lasting text clarity

Print that does not rub off, even when scratched

Eliminates complaints such as:

“I can’t read the instructions anymore.”

“The barcode wouldn’t scan.”

“The label rubbed off after a few days.”

Important for:

Shipping environments

Retail products

Daily-use items

Beauty and skincare packaging

Outdoor products

Waterproof Labels Reduce Customer Complaints by Improving Adhesive Performance

Why normal labels peel or fall off

Moisture, temperature changes, oils, and friction weaken adhesive bonds in standard paper labels.

Waterproof labels stay adhered

High-quality waterproof labels use adhesives that:

Stick to plastic, metal, glass, cardboard, and textured surfaces

Resist peeling in humidity

Stay secure in refrigeration and freezing

Grip even curved surfaces

Prevent edge-lifting

Prevents frustrations like:

“The label fell off.”

“The sticker came loose after one use.”

“The label slid off when I touched it.”

Industries That Benefit the Most from Waterproof Labels

1. Skincare & Beauty

Common customer complaints include:

Ingredient lists smearing

Branding peeling off

Tube labels rubbing off during use

Waterproof labels ensure the packaging remains premium and readable even with heavy handling and oil exposure.

2. Handmade Soap & Bath Goods

Labels often fail due to:

Steam

Moisture

Wet storage

Soap sweating

Waterproof labels keep bar wrappers and containers looking fresh.

3. Candles & Wax Melts

Heat and fragrance oils can:

Warp labels

Fade print

Make stickers slide

Waterproof labels maintain crisp safety instructions and branding.

4. Food & Beverage

Condensation, refrigeration, and spills cause paper labels to:

Bubble

Tear

Smear

Waterproof labels stay intact from production to consumption.

5. Frozen & Refrigerated Foods

Standard labels fail immediately in freezer cycles. Waterproof labels:

Resist frost

Handle thawing condensation

Maintain barcode readability

6. Cleaning Supplies & Chemical Products

Products with surfactants or solvents damage paper labels. Waterproof labels resist:

Household chemicals

Bleach

Cleaning agents

7. Shipping & Logistics

Customers complain when shipping labels:

Smear in the rain

Tear on conveyor belts

Peel on poly mailers

Waterproof shipping labels prevent delivery confusion and help keep carrier scanning smooth.

How Waterproof Labels Improve Product Professionalism

Unreadable labels send a negative message:

The brand is careless

The product is low-quality

Information is unimportant

Safety may have been overlooked

Waterproof labels communicate the opposite:

Professional packaging

Reliable quality

Attention to detail

Strong brand identity

Long-term usability

How Waterproof Labels Reduce Returns & Negative Reviews

Unreadable labels are often a direct cause of:

1-star reviews

Negative customer feedback

Unnecessary returns

Poor seller ratings

Examples of common review comments include:

“I couldn’t read the ingredients anymore.”

“The warning label rubbed off.”

“The barcode was unreadable.”

“The label was already peeling when it arrived.”

“After one use, the sticker smudged.”

Switching to waterproof labels dramatically reduces such incidents by ensuring the label stays readable throughout the entire customer journey.

Strategies for Using Waterproof Labels to Prevent Complaints

To maximize the customer experience, businesses should:

1. Use waterproof labels on all high-moisture products

Even partial exposure can ruin paper labels.

2. Choose the right size and placement

Labels should not be too small, curved excessively, or placed where they will rub off.

3. Ensure proper surface prep

Clean containers before labeling to ensure maximum adhesion.

4. Test labels in real-world conditions

Include:

Water exposure

Friction

Oils or lotions

Freezing/thawing

Heat and steam

5. Ensure text and icons are high-contrast

Readable labels help customers feel safer and reduce confusion.

Conclusion: Waterproof Labels Solve One of the Most Common Packaging Problems

“Unreadable” stickers are one of the top reasons customers lose trust in a brand, complain, or stop buying. Waterproof labels eliminate these problems by offering superior durability, readability, and adhesion in real-world environments.

They:

Resist water, oils, and heat

Stay readable for the product’s full lifespan

Prevent smudging, fading, and peeling

Make compliance information reliable

Improve brand professionalism

Increase customer satisfaction

For any business selling products exposed to moisture, handling, heat, or friction, waterproof labels are a powerful tool for reducing complaints and protecting brand reputation.

Direct Thermal Labels Suppliers – BETCKEY Label

FAQs

1. Why do customers often complain about unreadable labels?

Unreadable labels usually result from water exposure, oils, handling friction, temperature changes, or poor adhesives—all issues that waterproof labels are designed to prevent.

2. Are waterproof labels worth the investment for small businesses?

Yes. Waterproof labels reduce returns, negative reviews, and customer complaints while improving brand image and packaging durability.

3. Can waterproof labels be used on curved or moist surfaces?

High-quality waterproof labels adhere well to curved, smooth, or slightly moist surfaces, making them ideal for bottles, tubes, candle jars, and food containers.